ISO 16321-1:2021 for safety goggle, face shield

I – Introduction

II – Main modifications

III – Conclusion

- APPENDIX 1 – new tests

- APPENDIX 2 – new marking requirements

- APPENDIX 3 – new instruction requirements

I) Introduction

*This standard supersedes EN 166:2002, EN 169:2003, EN 170:2003, EN 171:2002, EN 172:1995, EN 175:1997 and EN 379+A1:2009.

*This document specifies general requirements for eye and face protectors, against occupational hazards.

*Transitional period until April 2025

*Normative references:

ISO 4007 gives the terms and definitions,

ISO 18526 tests methods,

ISO 18527 for specific sports,

ISO 19734, for the selection, use and maintenance of eye and face protectors

II) Modifications

ISO 16321-2 Additional requirements for protectors used during welding and related techniques

ISO 16321-3 Additional requirements for mesh protectors.

Change in the state of the art.

Many modified requirements and associated test methods (see Appendix).

III) Conclusion

The ISO 16321 series was developed following a general request to establish minimum requirements and tests methods for eye and face protectors, internationally marketed.

The protectors certified according to EN 166:2002, will no longer comply with the applicable essential health and safety requirements, in April 2025 (subject to the publication in the Official Journal of the European Union).

Each request for a re certification according ISO 16321 series, for a PPE that conforms to EN 166, will be considered on a case-by-case basis.

APPENDIX 1

New tests:

Attention non-exhaustive list as it does not include modified associated test methods

4.2 Physiological compatibility,

4.3 Construction and adjustment,

4.4 Cleaning and/or disinfection,

4.5 Headform(s)

5.2 Refractive power and prismatic power for plano lenses

6 Physical optical requirements for protectors

7 Physical and mechanical requirements for protectors

7.11 High mass impact, impact level HM (optional requirement)

7.16 Protection against streams of liquids (Optional requirement)

7.19 Protection against radiant heat (optional requirement) 7.20 Chemical resistance (optional requirement)

7.21 Use in explosive atmospheres (optional requirement)

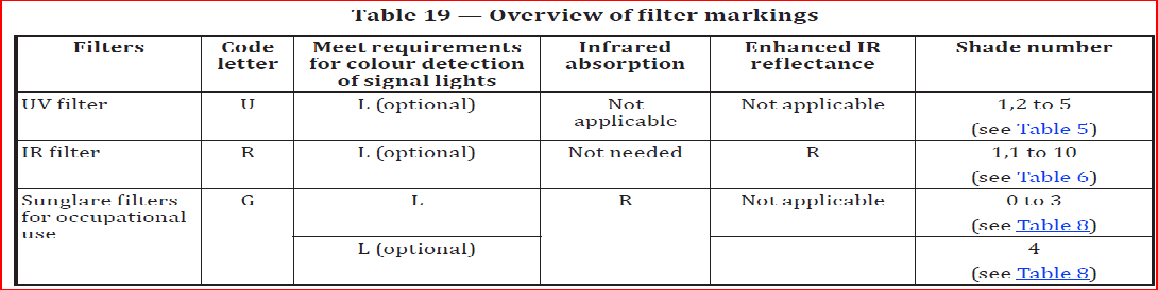

APPENDIX 2 Marking of protectors

f) applicable head size: If the manufacturer wishes to indicate the size of the headform(s) (according to ISO 18526-4) that theprotector will fit, the following symbols shall be added to the product marking:

— a single size is given by its respective symbol: 1-C12, 1-S, 1-M, 1-L, or 2-S, 2-M, 2-L

— multiple sizes are given by the symbols of the smallest and the largest size respectively, divided by a slash e.g. 1-M/1-L, 2-M/2-L

Specific national or regional regulations with regard to marking should be observed.

APPENDIX 3

Information to be supplied by the manufacturer :

g) the applicable headforms in accordance with ISO 18526-4, e.g. "This protector is appropriate for the headform 1-S. " This information shall be in the form of either markings on the frame, see 8.5, or separate information on labels, packaging, hang tags, etc., that accompanies the protector at the point of sale.

h) for protectors with non-uniform spectral transmittance in the visible region, add a warning "Protector can affect the recognition of colours and / or signal light detection.“

i) the following warning: "Protectors that have been subject to impact shall not be used and shall be discarded and replaced."

k) the following warning: "The protections corresponding to the code numbers/letter 7, 9, CH are provided by the complete protector only if the respective symbols are equal on both the lens and the frame."

q) if the requirement of field of view and/or transmittance for driving are not fulfilled the warning: "Not suitable for driving and road use" and/or the pictogram in accordance with ISO 7000, Reference No: 2952A or 2952B, (see also Figure 5) shall be added.